Which composite sheet is better?

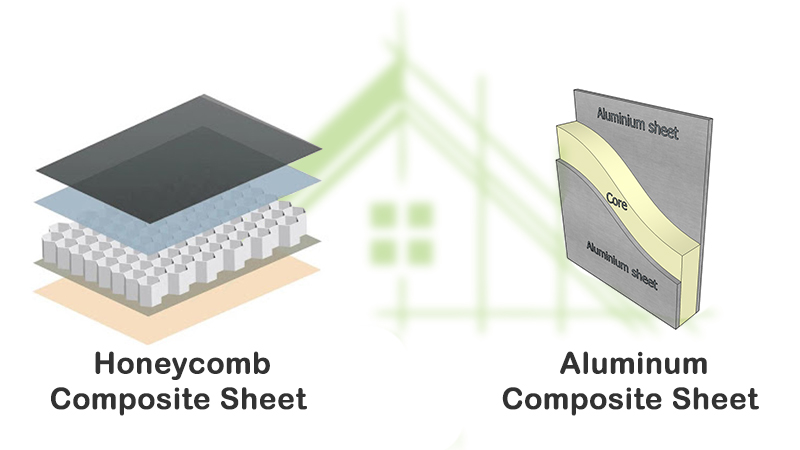

Aluminum composite sheet and honeycomb composite sheet (Honeycomb) are suitable materials for building’s facade.

What is the difference between aluminum honeycomb composite sheet and aluminum composite sheet? Which type of composite sheet is better?

We, as a professional composite sheet manufacturer, will make a comparison:

Aluminum honeycomb composite sheet (HONEY COMB)

Honeycomb composite sheet (HONEY COMB) is a composite that consists of rigid shells firmly attached to a light core. HONEY COMB aluminum composite sheet is a new composite material with a sandwich structure that combines two layers of aluminum foil. It is formed through an adhesive and an aluminum honeycomb core.

Aluminum honeycomb sheets are usually coated with fluorocarbon or polyester. Fluorocarbon coatings are more widely used than outdoor composite wall sheets due to their waterproof and self-cleaning properties, while Polyester coatings are mostly used for interior wall panels. The common materials of HONEY COMB composite sheet are foam and aluminum or Aramid. Honeycomb composite sheet is extremely light and strong.

Uses of Honeycomb Composite Sheet

HONEY COMB composite sheet is used when ultra-light assembly is required. The internal structure of airplanes (walls, floors, etc.) is usually made of honeycomb composite sheet instead of solids. Satellites, trains, and racing cars also use honeycomb composite sheet, although they are light, they lighten the weight.

Honeycomb Aluminum composite sheet can be compared to a sheet with lightweight, high resistance, good strength and flat surface, which can be used for structures, partitions and decorations, etc. The thickness of honeycomb aluminum sheet can be selected according to the usage from 6 to 100 mm and also the shape can be turned into a flat plate, a curved plate or a double curved plate according to the special needs. Honeycomb aluminum sheet not only has good forming flexibility but also does not deform easily after being formed.

Due to the above advantages, aluminum honeycomb sheets are widely used in aviation, aerospace, transportation, construction, military and other items. For example, it is used for exhibitions of missiles, aircraft wings and depots, train cabin and floor, car shells and doors, roofs and curtain walls.

Using vertical wings and tail, as well as the cockpit, cargo floor and door or cargo compartment, honeycomb panels can effectively reduce aircraft weight and improve the handling of moving parts.

The color of the aluminum composite sheet depends on the coating on the surface

Aluminum Composite sheets (ACP) are flat sheets consisting of two thin-walled aluminum sheets attached to a non-aluminum core. ACP is often used to insulate and mark the exterior cladding or building facades.

The similarities between composite sheets

Aluminum composite sheets and aluminum honeycomb sheets are much more popular than composite sandwich panels. They are widely used in curtain walls, building partitions, which in comparison with other materials, aluminum composite sheets have many similar advantages such as lightness and low density, high resistance and good strength, resistant to vibration, no pollution, energy saving and environmental protection, and they are easy to clean.

The difference between aluminum composite sheet and aluminum honeycomb sheet

Aluminum composite sheet is lighter than aluminum honeycomb sheet. Although these two materials are composite materials with sandwich panel structure, a plastic core is used in the aluminum composite sheet plate and an aluminum honeycomb core layer is used in the aluminum honeycomb plate, which is heavier than plastic core.

Due to given analysis, you can see the difference between aluminum composite sheets and aluminum honeycomb sheets. If you ask, which composite wall panel is better? It’s hard to find the right answer. You need to choose the composite wall covering that suits you best. In addition, the most important thing is your budget.